Applications

SinOne AI Touch Adaptive Technology

The capacitive touch technology offers advantages such as easy operation, fast response, low cost, and no need for physical openings. Therefore, it is widely used in industries such as smart home appliances, consumer electronics, and IoT.

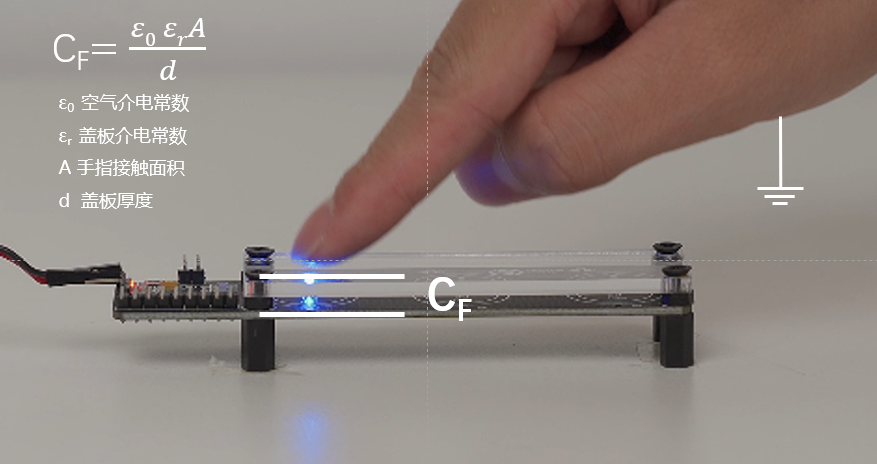

Capacitive touch is based on detecting the capacitance of a finger (CF), as shown in the diagram below:

Figure 1: Principle of Capacitive Touch

The capacitance of a finger (CF) is directly proportional to the dielectric constant of the charge-conducting medium and the contact area of the finger, while being inversely proportional to the thickness of the charge-conducting medium.

Therefore, the dielectric material, its thickness, and user touch habits have a significant impact on touch performance. Additionally, it is susceptible to interference from electric, magnetic, and thermal factors.

To achieve high-sensitivity and reliable touch performance, the detection circuit must have extremely high resolution and interference immunity, while stable and reliable algorithms are required to process and provide feedback on the signals.

SinOne Touch Technology:

SinOne touch MCU integrates a capacitive detection circuit with a signal-to-noise ratio of up to 100:1 and a resolution of 0.1pF. Equipped with a comprehensive touch library algorithm, it offers both sensitivity and reliability. It can consistently pass the 10V dynamic CS test and has been widely applied in smart home appliances, industrial control, automotive electronics, and consumer electronics.

Additionally, SinOne EasyCode MagicBox development platform provides a graphical touch debugging interface, allowing the development and debugging of touch products to be completed in just 5 minutes. This significantly lowers the development threshold and enhances development efficiency.

AI Touch Adaptive Technology:

In the process of product development and manufacturing, touch key parameter configurations are often fixed. As a result, the touch parameters debugged during project development may lead to discrepancies in sensitivity and consistency after mass production due to differences in the touch panel structure or assembly, causing issues with touch key operation. This may require software modifications and new parameter configurations.

Additionally, the same type of PCB board may require different programs for different models, increasing the complexity of program development and management.

Although general-purpose touch MCUs can address environmental variations through baseline updates or slight touch sensitivity adjustments, the adaptation range is relatively limited, making it difficult to fully resolve the issues encountered in development and production.

SinOne's AI touch adaptive solution, developed using SinOne’s high-sensitivity touch MCU and next-generation touch algorithm library, can self-learn and adapt to environmental changes, structural differences, and variations in user habits, intelligently adjusting touch parameters. By dynamically identifying changes in user touch and comparing them to the expected model, any deviation in the actual response will automatically trigger adjustments to the touch parameters, ensuring that user touch responses remain within the expected range. Continuous response calculations and parameter adjustments keep touch sensitivity at its optimal level.

Figure 2: SinOne AI Touch Adaptive Technology

SinOne AI touch adaptive solution addresses the challenge of repeatedly adjusting touch programs during the development and production of touch products, while also enhancing the user touch experience:

Development Process:

1.Touch development and debugging are no longer necessary. After just 3-5 touch interactions, the system can automatically adapt and configure touch parameters.

Production Process:

1.The same PCB board can accommodate different thicknesses and materials without adjusting the CODE, ensuring stable touch performance.

2.Automatically adapts to assembly variations and structural gaps, reducing the need for recalibration steps.

User Experience:

1.Automatically adapts to seasonal changes in temperature and humidity, maintaining consistent user touch experience.

2.Automatically adjusts to different user touch habits, ensuring sensitive touch response for every user.

3.Automatically dapts to structural deformation caused by aging and wear, minimizing the impact on touch performance and reducing post-sale maintenance needs.

Summary:

SinOne continues to innovate in touch technology:

l In 2017, SinOne introduced the industry’s first innovative air-touch MCU.

l In 2020, the MCU software development platform, EasyCode MagicBox, was launched, offering a fully graphical development interface and touch debugging times as fast as 5 minutes.

l The AI touch adaptive technology marks another leap in productivity, enabling touch MCUs to be "customized" without the need for debugging and allowing dynamic learning and adaptation.

Figure 3: Continuous Iteration of SinOne Touch Technology

Applicable Part Number

Add to compare

Compare(0)

![]() export

export